Complete Pump Solutions

From expert consultation to precision installation and ongoing support, we deliver end-to-end engineering solutions that keep your operations running at peak performance.

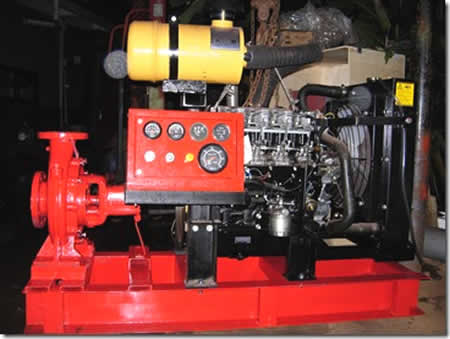

Fire Pump Sets are critical in maintaining optimal water pressure within fire protection systems, especially in large buildings and industrial complexes. These sets typically include a pump, driver, controller, and auxiliary equipment. The pump, usually powered by an electric motor or diesel engine, activates when the system detects a drop in water pressure, ensuring a consistent flow of water to combat fires. Fire Pump Sets are built to comply with stringent industry standards, ensuring durability, reliability, and performance under emergency conditions. They play a vital role in safeguarding lives and property by ensuring fire suppression systems function effectively when needed most.

Jockey Pump Sets are smaller pumps used in fire protection systems to maintain the pressure within the system at a predefined level. These pumps automatically start when the pressure drops below a set threshold due to minor leaks or system tests, thus keeping the system primed and ready for action without activating the main fire pump.

By maintaining consistent pressure, jockey pumps ensure that the main fire pump is reserved for significant pressure drops caused by real fire situations, reducing wear and tear and enhancing the reliability of the fire protection system. Jockey Pump Sets typically include the pump, controller, pressure switch, and necessary piping and fittings, designed to seamlessly integrate into the overall fire protection setup.

Booster Pump Sets are essential for increasing water pressure in systems where the existing pressure is too low to meet the demand. These sets include a pump, motor, and control panel, and are often used in high-rise buildings, irrigation systems, and municipal water supply networks.

By boosting the pressure, these pumps ensure that water reaches all parts of the system with sufficient force, improving the efficiency and performance of water distribution. Booster Pump Sets are available in various configurations, including single-stage and multi-stage pumps, to suit different pressure requirements and applications.

They are designed for easy installation and operation, featuring automatic controls that adjust the pump’s performance based on real-time demand. With their ability to provide a reliable and steady water supply, Booster Pump Sets are crucial for maintaining the functionality and comfort of modern plumbing systems.

Control Panels are integral to managing and automating electrical systems, encompassing a range of components such as switches, relays, circuit breakers, and programmable logic controllers (PLCs). These panels serve as the interface between the user and the equipment, allowing for precise control, monitoring, and diagnostics. In industrial applications, Control Panels manage complex machinery, process systems, and production lines, ensuring optimal performance and safety. In commercial and residential settings, they regulate HVAC systems, lighting, and other electrical installations.

Control Panels can be custom-designed to meet specific requirements, incorporating features like touchscreen interfaces, remote monitoring capabilities, and advanced safety mechanisms. They are built to comply with industry standards and regulations, ensuring durability and reliability in various operating environments. By centralizing control functions, Control Panels enhance operational efficiency, reduce downtime, and facilitate maintenance, making them indispensable in modern electrical systems.

Dosing Systems are engineered to deliver precise quantities of liquids, chemicals, or other substances into a target system, ensuring accurate and consistent dosing required for various industrial, commercial, and laboratory applications. These systems typically consist of a pump or metering device, control unit, and storage containers. They are used extensively in water and wastewater treatment for adding disinfectants, coagulants, or pH-adjusting chemicals, as well as in chemical processing industries for injecting reagents, catalysts, or additives.

In pharmaceutical and food industries, Dosing Systems ensure the correct proportions of ingredients are used, maintaining product quality and safety. The systems can be manually or automatically controlled, with advanced models featuring programmable settings, real-time monitoring, and feedback mechanisms to adjust dosing rates as needed. By providing precise control over the dosing process, these systems help optimize efficiency, reduce waste, and ensure compliance with stringent regulatory standards. Dosing Systems are available in various configurations to meet specific application needs, making them vital for processes that demand high precision and reliability.

Ready to Optimise Your Flow Systems?

Our team of experts is ready to analyse your needs and design a solution that perfectly matches your operation. Contact us today for a consultation and discover how our decades of expertise can work for you.